Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Understanding the Role of an Optical Fibre Diameter Analyser in Optical Communications

Blog Article

Exactly How an Optical Fibre Diameter Analyser Boosts Top Quality Control in Fibre Manufacturing

The integration of an Optical Fibre Diameter Analyser right into Fibre production processes stands for a significant innovation in high quality control approaches. By providing real-time, precise dimensions of Fibre diameters, this technology attends to the crucial demand for consistency in production requirements.

Relevance of Fibre Diameter Measurement

Accurate measurement of Fibre Diameter is essential in the field of optical Fibre technology, as it directly affects the performance and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying capacity, depletion, and overall transmission efficiency. Accuracy in determining Fibre Diameter guarantees that the optical buildings are kept within defined resistances, which is essential for ideal signal honesty.

Variations in Fibre Diameter can result in increased losses as a result of scattering and modal dispersion, impacting the top quality of data transmission. In high-speed communication systems, such disparities can result in considerable deterioration of signal quality, resulting in information mistakes and decreased performance. Additionally, constant Fibre Diameter is crucial for compatibility with ports and splicing technologies, which are important components of Fibre optic networks.

Quality assurance processes in Fibre manufacturing heavily rely upon precise Diameter measurements to make certain conformity with industry requirements. By carrying out durable measurement techniques, suppliers can enhance product dependability, minimize waste, and enhance total system efficiency. Hence, the value of Fibre Diameter measurement can not be overemphasized, as it functions as a foundation in the development of optical Fibre innovation and its applications in modern-day communication networks.

How the Analyser Works

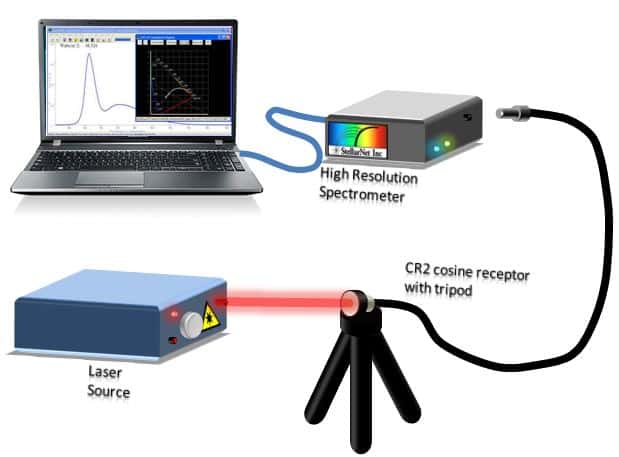

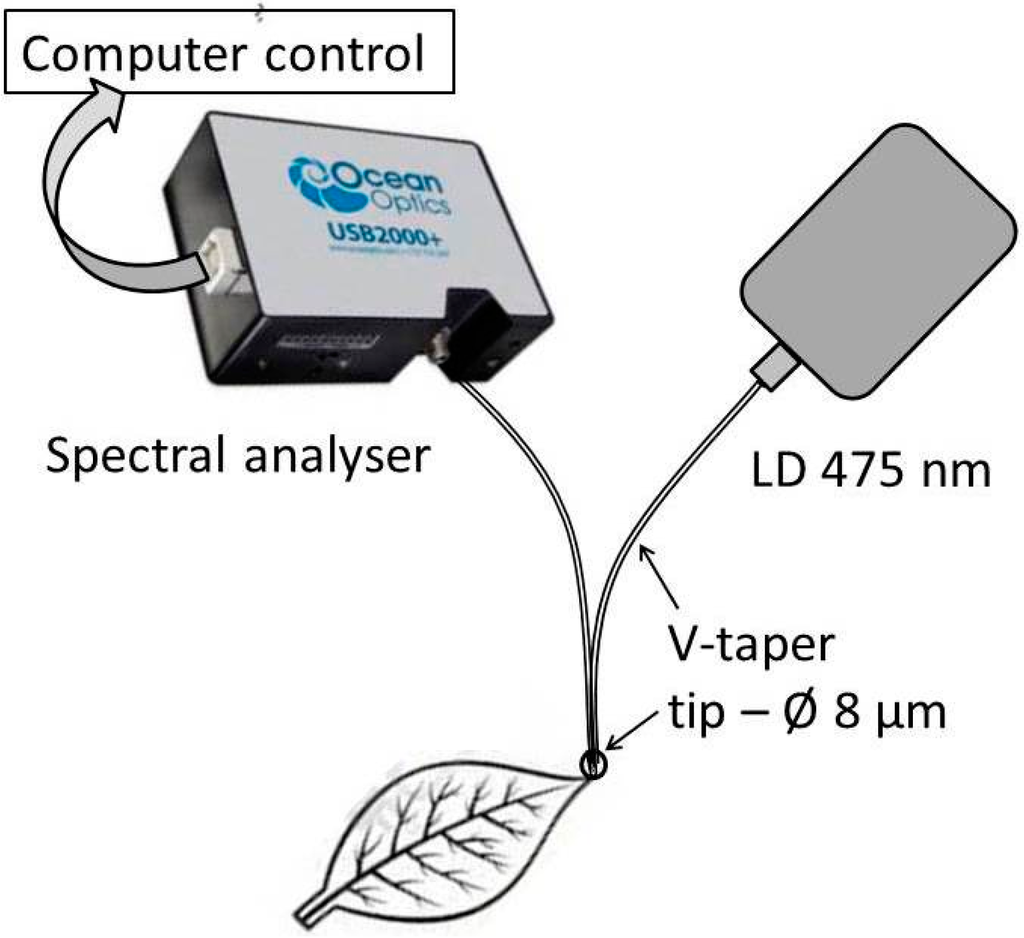

The reliable measurement of Fibre Diameter counts on innovative logical techniques that make sure accuracy and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser technology and progressed photo handling algorithms to precisely examine the Diameter of fibres as they are generated

Originally, a laser beam of light is directed at the relocating Fibre, developing a cross-sectional shadow. The analyser captures this darkness using high-resolution electronic cameras placed purposefully along the assembly line. The caught pictures are after that processed in real-time to establish the Fibre's Diameter with extraordinary accuracy.

The system utilizes advanced algorithms that account for various variables, consisting of variations in light strength and ecological problems, to enhance measurement integrity. It can find minute changes in Diameter, such as variations that could take place during the manufacturing process.

In addition, the analyser is capable of dealing with multiple fibres at the same time, boosting throughput without compromising precision. By providing instant feedback on the Diameter, the Optical Fibre Diameter Analyser plays an essential duty in maintaining rigorous top quality control criteria, making sure that the end product fulfills sector specifications and client needs.

Advantages of Real-Time Tracking

While typical methods of keeping track of Fibre Diameter usually involve taxing post-production checks, real-time surveillance significantly enhances the effectiveness and high quality of optical Fibre production. optical fibre diameter look at here analyser. This aggressive strategy allows makers to recognize variances in Fibre Diameter as they occur, as opposed to waiting until production is total to assess top quality

By continually measuring the Diameter throughout production, suppliers can make certain that the fibers satisfy rigid specifications, bring about lowered irregularity and boosted uniformity. Real-time tracking also makes it possible for immediate restorative activities to be taken, reducing waste and stopping malfunctioning fibers from going into the supply chain.

In addition, this technology promotes enhanced data collection and evaluation, giving insights into production patterns and possible areas for renovation. Such data-driven decision-making equips suppliers to optimize procedures and preserve high requirements of top quality control.

Furthermore, real-time surveillance promotes a society of continuous renovation within the production atmosphere. Staff members are more engaged when they can see the effect of their operate in real-time, leading to increased accountability and a dedication to excellence. Overall, the execution of real-time surveillance systems in optical Fibre manufacturing equates to premium item top quality and enhanced customer complete satisfaction.

Influence On Manufacturing Efficiency

Carrying out optical Fibre Diameter analysers considerably official website boosts production effectiveness by streamlining the production process. These devices facilitate continuous surveillance of Fibre Diameter, enabling suppliers to identify deviations in real-time. By recognizing inconsistencies quickly, assembly line can be adjusted swiftly, reducing downtime and reducing the possibility of producing defective products.

Additionally, the combination of these analysers into the manufacturing process makes it possible for much better source allowance. With precise Diameter dimensions, operators can optimize material usage, ensuring that sources are not wasted on flawed fibres. This accuracy additionally adds to less rework and ditch, inevitably decreasing manufacturing costs.

The automation provided by optical Fibre Diameter analysers reduces reliance on hand-operated evaluations, which are often time-consuming and prone to human error. Therefore, staff members can concentrate on more calculated tasks, improving overall performance.

Moreover, the data created from these analysers can educate process improvements and assist in much better decision-making. By analyzing fads in Fibre Diameter variants, manufacturers can carry out proactive actions to enhance manufacturing techniques and maintain consistent high quality. In recap, optical Fibre Diameter analysers play a critical duty in increasing production effectiveness, leading to higher quality result and enhanced profitability.

Study and Success Stories

Across numerous sectors, instance studies highlight the transformative impact of optical Fibre Diameter analysers on manufacturing processes. One famous example is a leading telecoms company that dealt with difficulties with inconsistent Fibre sizes, leading to enhanced denial rates. By integrating an optical Fibre Diameter analyser, the business achieved real-time surveillance of Fibre measurements, causing a 30% reduction in problems and substantial cost financial savings.

Furthermore, a research study establishment find more concentrating on sophisticated products made use of optical Fibre Diameter analysers to refine their speculative processes. The analyser's capacity to give thorough insights right into Fibre uniformity enabled the development of cutting-edge products with enhanced performance attributes.

These success tales highlight the necessary duty of optical Fibre Diameter analysers in enhancing quality control, enhancing production efficiency, and driving technology across varied sectors.

Conclusion

In final thought, the Optical Fibre Diameter Analyser plays a pivotal duty in improving quality control within Fibre manufacturing. As shown via numerous case studies, the analyser verifies necessary for attaining premium product high quality in Fibre manufacturing.

The implementation of optical Fibre Diameter analysers enabled for strict top quality control, making certain that the created fibers satisfied exacting industry criteria.In final thought, the Optical Fibre Diameter Analyser plays a pivotal function in boosting top quality control within Fibre production.

Report this page